Győr, Hungary – Embracing the Future of E-Mobility

In a move towards the future of transportation, Audi has begun manufacturing electric motors for the Premium Platform Electric (PPE) in Győr, Hungary. This marks a moment for Audi, highlighting its dedication to innovation and sustainable automotive solutions. The compact and efficient electric motors produced in Győr will initially be used in the Audi Q6 e tron series ushering in an era for the Audi`s electric vehicle range.

Győr – The Hub of Electric Innovation

Emphasizing the importance of Győr factory in this endeavor, Audi CEO Gernot Döllner states that “Győr is predestined for the production of these highly compact and efficient electric motors for the PPE. The highly qualified team at the site has already built over 400,000 electric drive systems since 2018, which is invaluable experience.” This Hungarian city has now become the center for Audi`s initiatives boasting a skilled team that has already manufactured over 400,000 electric drive systems since 2018.

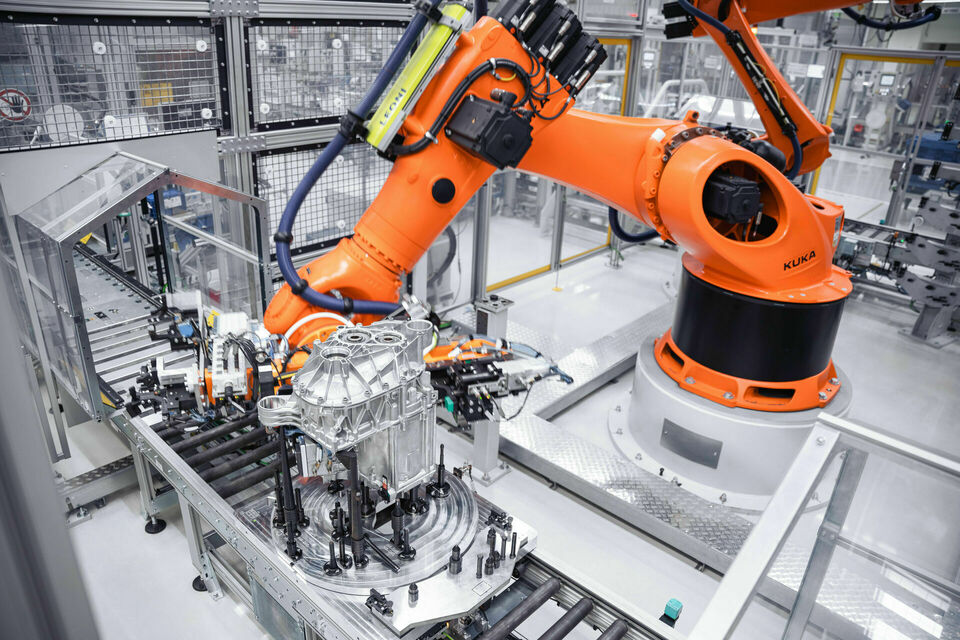

Striving for Excellence – Audi`s Impressive Production Facility

Audi has made investments to transform Győr into an electrification powerhouse. The production site spans 15,000 meters and is dedicated to crafting stators and transmission components with meticulous attention to detail.

In this facility, the assembly of axles for the PPE is also carried out, contributing to the production of electric drivetrains. The Győr facility does not serve Audi but also supplies electric motors to Porsche.

Precise Production Process – Crafting Electric Motors with Accuracy

To manufacture motors for the PPE, Audi has introduced three production lines that highlight the brand’s dedication to precision and efficiency. The stator production line involves 28 work stages while the transmission components line consists of 15 steps. Assembling an axle requires 190 individual steps. Around 700 dedicated employees work in three shifts to produce up to 2,000 motors per day for the PPE, demonstrating Audi’s large-scale venture into electrification.

Global Environmental Responsibility – Audi`s Comprehensive Approach

The electric motor production facility in Győr plays a key role in supplying both Audi and Porsche, underscoring the significance of this Hungarian city within Audi’s global network. Audi’s dedication to sustainability extends beyond producing vehicles. Since 2020, Győr`s production has achieved carbon neutrality by leveraging Europe’s roof-mounted photovoltaic system and being Hungary’s leading industrial consumer of geothermal energy.

To ensure that the transportation of motors from Győr to Ingolstadt has a carbon-neutral impact Audi has joined forces with DB Cargo, a transport and logistics company. This comprehensive approach aligns with Audi’s vision for the future of manufacturing as part of their 360factory initiative.

Celebrating a 30-year success story, Audi Hungaria marks a milestone as production begins for the PPE. Established in 1993, it has evolved into the world’s powertrain plant, becoming Hungary’s first premium car manufacturer. Some notable achievements of Audi Hungaria include being the producer of the CUPRA Terramar and contributing to enhanced synergies in the production network.

Technical Development

Technical Development at Audi Hungaria plays a role in product development for both Audi and the Volkswagen Group. With 12,000 employees so far, it has become an important player in the Hungarian industry by investing around twelve billion euros since its inception.

Final Thoughts

Looking forward to the future, Audi`s venture into motor production in Győr reflects their dedication to innovation and sustainability. As anticipation builds for the debut of the Audi Q6 e-tron this year, the Hungarian facility in Győr remains at the forefront of the Audis production network.

Audi has an impressive history. They are committed to sustainability and shaping the future of transportation. From the heart of Hungary, their electrified vision is vibrant and promising.

Source: audi-mediacenter.com

Audi Production of Electric Motors for PPE Media Gallery